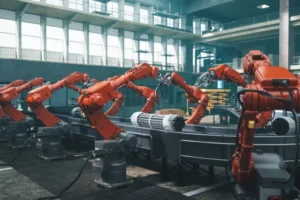

Colombia’s economy is vibrant & growing. Its manufacturing sector booms—from food, beverages to pharmaceuticals, industrial goods. Behind this growth, demand for efficient, reliable, innovative packaging solutions rises. For businesses on Colombia aiming to optimize production lines, choosing right packing machine manufacturer is an crucial decision.

While many global players serve Colombian market, this list focuses on companies with strong direct presence, significant market share, or specialized solutions highly relevant to country’s diverse industries.

Here’s look at some leading packing machine manufacturers making impact in Colombia:

Lintyco Pack

As prominent global player, Lintyco Pack brings cutting – edge technology & extensive experience to Colombian market. It specializes in advanced Vertical Form Fill Seal (VFFS) & Horizontal Form Fill Seal (HFFS) machines. Lintyco Pack offers robust, flexible solutions for wide array of products—snacks, powders, liquids, delicate items. Its focus on efficiency, sustainability, tailored configurations makes it top choice for businesses aiming for high – performance, future – proof packaging operations.

With strong commitment to local service & support, Lintyco Pack is rapidly becoming preferred partner across various Colombian industries.

P.E. Labellers

Global leader in labeling solutions, P.E. Labellers provides high – tech, precise labeling machines essential for product presentation & traceability. While main operations are elsewhere, its advanced rotary & linear labelers are widely available through strong distribution networks on Colombia, serving beverage, food, pharmaceutical sectors.

Tecnoempaque SAS

Proudly Colombian company, Tecnoempaque SAS specializes in providing integrated packaging solutions. It offers range of machinery—form – fill – seal machines, cappers, conveyors. It often sources from international partners but provides strong local assembly, integration, after – sales support.

Indumak

Based in Brazil, Indumak has significant presence in Latin America, including Colombia. It offers wide array of packaging solutions, particularly for solid, granular, powdered products. Its robust bagging machines, balers, palletizers are well – regarded for durability & performance in demanding environments.

Sidel

Global leader in PET packaging solutions for beverages, food, home, personal care, Sidel has strong footprint on Colombia. It offers complete line solutions—from blow molding to filling & labeling. This makes it critical partner for large – scale production facilities.

Bosch Packaging Technology

Now operating as Syntegon, this company maintains legacy of German engineering excellence. Through dedicated agents & support, Syntegon’s advanced packaging & process technology for pharmaceuticals, food, confectionery is highly valued by Colombian industries seeking precision & reliability.

Smurfit Kappa

While primarily known for paper – based packaging materials, Smurfit Kappa often works closely with clients to recommend & integrate suitable packaging machinery that complements its innovative packaging designs, providing more holistic solution. Its strong local presence on Colombia makes it important player.

ULMA Packaging

From Spain, ULMA Packaging offers diverse range of packaging machines for various industries—food, medical, consumer goods. Its thermoforming, tray sealing, flow pack machines are well – known for flexibility & efficiency, with good representation on Colombia.

Comexi

Specializing in machinery for flexible packaging industry, Comexi is Spanish company that provides slitting, laminating, printing solutions. For Colombian converters & large – scale producers of flexible packaging, Comexi’s technology is vital for creating high – quality packaging materials.

Focke & Co.

German manufacturer known for high – speed packaging machines, particularly for tobacco & general consumer goods industries, Focke & Co. serves Colombian market through specialized local partners, offering sophisticated & reliable equipment for demanding production volumes.

How to Choose Right Packing Machine

Selecting ideal packing machine for your business is strategic decision. It can significantly impact operational efficiency, product quality, bottom line. Here are key factors to consider:

Understand Your Product:

- Nature of Product: Is it solid, liquid, powder, granular, delicate, or sticky? This will dictate type of filling & sealing mechanism required.

- Product Volume & Weight: Smaller, lighter products may use different machines than large, heavy items.

- Shelf Life Requirements: Does your product need modified atmosphere, vacuum sealing, or special barrier properties?

Define Your Packaging Needs:

- Type of Packaging: Do you need bags (pouches, stand – up, pillow), cartons, bottles, trays, or blister packs?

- Packaging Material: What kind of film, paper, or rigid material will you be using? Ensure compatibility with machine.

- Desired Aesthetics: How should final package look? Consider sealing quality, print registration, overall presentation.

Evaluate Production Capacity & Speed:

- Required Output: How many packages per minute or hour do you need to produce to meet demand?

- Scalability: Do you anticipate future growth that might require higher speeds or more versatile machines?

- Changeover Time: How quickly can machine be switched to package different products or sizes? Minimize downtime.

Consider Automation Level:

Manual, Semi – Automatic, or Fully Automatic: Your budget, labor availability, production volume will influence this choice. Fully automatic systems offer highest efficiency but require larger initial investment.

Assess Space & Layout:

- Available Footprint: Do you have enough space on your production floor for machine & its peripheral equipment (conveyors, feeders, etc.)?

- Integration: How will new machine fit into your existing production line?

Focus on Quality & Durability:

- Construction Materials: Look for robust construction, especially with food – grade stainless steel for hygiene – sensitive applications.

- Reliability: Research manufacturer’s reputation for machine uptime & longevity.

Prioritize After – Sales Support & Service:

- Local Support: Does manufacturer or their representative offer strong local technical support, spare parts availability, maintenance services on Colombia? This is critical for minimizing downtime.

- Training: Is operator training provided?

Budget & ROI:

- Initial Investment: Balance upfront cost with long – term benefits.

- Operating Costs: Consider energy consumption, maintenance, spare parts.

- Return on Investment (ROI): How quickly will machine pay for itself through increased efficiency, reduced labor, minimized product waste?

Look for Flexibility & Future – Proofing:

- Modularity: Can machine be easily upgraded or adapted to new products or packaging types in future?

- Sustainability Features: Does it support eco – friendly packaging materials or offer energy – saving features?

Conclusion

Colombia’s dynamic industrial landscape offers tremendous growth opportunities. Efficient packaging is at heart of capitalizing on these prospects. The manufacturers listed above—including Lintyco Pack with its advanced VFFS & HFFS solutions—represent pinnacle of packaging technology & service available in market.

By carefully considering your specific product needs, production goals, crucial factors for selecting right machine, Colombian businesses can make informed decisions. These decisions drive efficiency, ensure product integrity, & ultimately, secure competitive edge in their respective industries. Investing in right packing machine isn’t just about automation; it’s about investing in your future success.