Valued at USD 458.55 billion on 2024, it’s set to nearly double by 2032. The sector now covers vitamin gummies, herbal extracts, functional drinks, and more. But real battleground isn’t laboratory anymore; it’s packaging line. Here, product quality, regulatory compliance, brand trust either hold firm—or unravel.

Market Racing Ahead of Production Floor

Consumer demand for personalized wellness pushes annual industry growth over 10%. Most brands now juggle dozens of SKUs—sleep gummies, immunity stick packs, protein pouches. Each has distinct barrier, dosing, labeling requirements. That complexity hits where it hurts most:

- Changeover drag:Every formula swap can cut Overall Equipment Effectiveness (OEE) by 10–15% when fillers and baggers aren’t precisely synchronized.

- Downtime dominoes:A single film jam or mis – aligned seal can idle the line, causing cascading labor and scrap costs.

- Regulatory risk:Misprinted Supplement Facts panels or illegible batch codes trigger recalls, fines, reputational damage. In nutraceutical sector, transparency is non – negotiable.

Packaging as Engine of Efficiency—not An Afterthought

In fast – growing nutraceutical plants, packaging is first physical interface between precisely controlled lab environment and chaos of global logistics. Done right, it must do three things at once:

- Protect potency. Moisture -, oxygen -, UV – barrier films keep botanicals and fragile actives stable through shelf life.

- Prove compliance. FDA – formatted Supplement Facts, tamper – evident seals, child – resistant closures show due diligence to regulators and consumers.

- Delight buyer. Clean graphics, resealable zippers, turnkey e – commerce durability boost unboxing experience, defend premium price points.

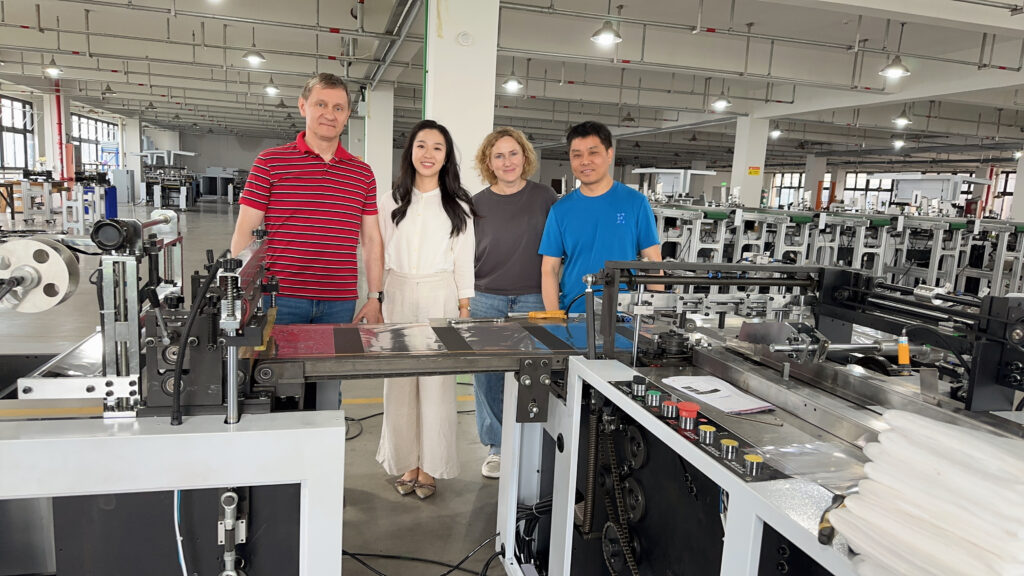

Lintyco: Designing Efficiency into Every SKU

Lintyco engineers packaging as integrated system. It pairs high – barrier films with purpose – built machinery for powders, liquids, or gummies—not as isolated parts. Key examples:

- Vertical Form – Fill – Seal (VFFS) for powders – up to 60 bags /min, with ±0.1% fill accuracy. Plus tool – free changeovers cut setup time in half.

- Stick – pack and sachet machines for single – serve immunity shots—servo – driven sealing guarantees uniform stick lengths even at 300 units /min.

- Gummy candy solutions isolate oiled vs. sanded gummies to stop sugar bloom and oil migration.

By validating film – to – machine compatibility in – house, Lintyco helps brands hit OEE targets above 92%—well above segment norm of 85% for multi – component lines.

Meeting Triple Mandate: Speed, Safety, Sustainability

Speed: Fighting Changeover Clock

Data from multi – line nutraceutical plants show filler – bagger transitions are top source of hidden downtime. Lintyco’s PLC – driven recipe management stores optimal seal temperatures, jaw pressures, auger settings for each SKU. Operators switch formulas with one touchscreen command—no manual tweaks, no re – calibration delays.

Safety: Tamper – Evidence by Design

Modern regulations need at least one tamper – evident feature on most ingestibles, two on two – piece capsules. Lintyco integrates shrink – bands, induction liners, or color – shift films straight into its filling heads. This eliminates extra pass through secondary equipment. It ensures every bottle meets FDA and TGA guidance without slowing throughput.

Sustainability: Closing Loop without Compromise

Eco – minded shoppers spot “greenwashing” instantly. So mere marketing claims don’t suffice. High – clarity mono – material PP pouches and PLA jars now offer comparable oxygen barriers, cutting lifecycle emissions up to 71%. Lintyco’s material library has:

| Material | Key Benefit | Typical Use |

|---|---|---|

| Recyclable PP mono – film | 71% lower CO₂ vs. multilayer | Stand – up pouches |

| PLA bio – jars | Compostable, plant – based | Capsules, chewables |

| HDPE drop – off films | In – store recycle ready | Stick – pack overwrap |

Regulatory Reality Check

Label claims, font sizes, batch traceability are audited with same rigor as pharmaceutical dossiers. Recent FDA warning letters cite “illegible expiration dating” and “incorrect serving size” among top violations. Lintyco mitigates these pitfalls via:

- Vision – guided print inspection rejects any pouch with off – center Supplement Facts or blurred lot codes before case – packing.

- Electronic serialization links filler weight data to unique 2D code, meeting emerging EU and U.S. trace – and – trace mandates.

Calculating ROI of Integrated Packaging

A new supplement brand replaced legacy knock – down fillers with Lintyco’s servo VFFS. It documented:

| Metric | Before | After | Net Gain |

|---|---|---|---|

| Changeover Time | 45 min | 12 min | −73% |

| OEE | 78% | 93% | +15 pp |

| Annual Scrap | 5.1% | 1.4% | −3.7 pp |

| Payback Period | — | 11 months | — |

Reduced film waste alone offset 40% of capital cost in year one. Faster SKU launches opened new seasonal revenue windows.

Conclusion

Race from lab bench to customer label depends on packaging that’s fast, fail – safe, future – ready. Manufacturing efficiency isn’t operational nicety anymore; it’s strategic imperative. By uniting high – barrier films, agile machinery, airtight compliance in one integrated platform, Lintyco helps nutraceutical innovators scale without compromise. It keeps promise of better health intact from factory floor to consumer hand.

Ready to tighten your line and widen margins? Explore Lintyco’s full suite of nutraceutical packaging systems. Book a one – to – one engineering consult Now .